How to Boost Your Brand with Customized Plastic Spout Caps

Learn how Xinda Pelosi helps boost Xinda Pelosi with customized plastic spout caps. We're a leading manufacturer of high-quality, bespoke plastic spout caps designed to enhance your product's appeal and functionality. Discover how customized packaging elevates Xinda Pelosi. Contact us today for a quote!

- What is a Custom Plastic Spout Cap? Why is it So Important?

- Definition of Custom Plastic Spout Cap

- The Role and Importance of Customization in Modern Packaging

- The Main Advantages of Using Custom Plastic Spout Caps in Packaging

- Enhanced Product Functionality and Leak Prevention

- Better Consumer Convenience and Usability

- Industries that Benefit Most from Custom Plastic Spout Caps

- Food and Beverage Industry Applications

- Household Cleaning and Chemical Products

- Personal Care and Cosmetic Packaging

- Baby and Childcare Product Solutions

- Automotive and Industrial Lubricants

- How to Choose the Right Custom Spout Cap Manufacturer

- Why Choose the Custom Spout Cap Manufacturer Xinda Pelosi?

- Common Mistakes to Avoid When Customizing Spout Caps

- Ignoring Material Compatibility with Product Formulas

- Overlooking User Experience in Cap Design

- Skipping Functional Testing Before Mass Production

- Choosing Style Over Structural Integrity

- Failing to Align Cap Design with Filling and Sealing Machines

- Conclusion

What is a Custom Plastic Spout Cap? Why is it So Important?

Consumer market competition drives packaging to become the initial encounter between products and prospective buyers. Marketable branding outcomes through first-time product encounters depend on detailed packaging components where caps and closures are essential factors for usability and branding alignment. The significance of customized plastic spout caps has risen dramatically in various industrial sectors. Product dispensing caps function for practical purposes yet provide brands with space to create designs that meet the precise requirements of their target market.

Definition of Custom Plastic Spout Cap

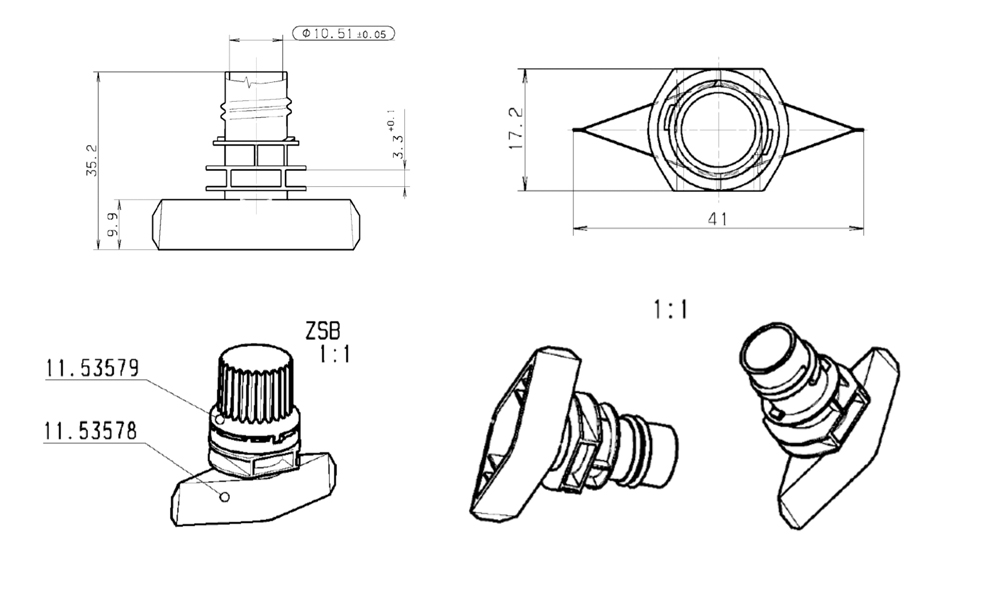

The custom plastic spout cap serves as a specialized closure that engineers to meet particular product specifications instead of adopting standard universal designs. The spout in this closure device serves as a mechanism to precisely dispense various liquid and gel substances. Custom plastic spout caps serve as packaging solutions for condiments and cleaning agents as well as personal care products. Custom-made caps differ from generic ones through their variable dimensions as well as their discretionary dispensing systems and product materials and color schemes that match brand preferences.

The Role and Importance of Customization in Modern Packaging

Companies need to provide customized packaging solutions which have developed into a fundamental business strategy. The design of a spout cap specifically made for consumer usage habits leads to better satisfaction levels which boosts customer loyalty and repeat buying behavior. Customization plays a strategic role to maintain product integrity because it allows selection of materials which are compatible with formulas and block leaks and contaminations. A product's branding benefits from unique cap shapes and colors featuring logos which help consumers identify products among other products on store shelves. Brands understand customized plastic spout caps serve dual purposes as packaging accessories and operational tools which support their marketing initiatives and operational needs.

The Main Advantages of Using Custom Plastic Spout Caps in Packaging

Brands now prioritize package components that deliver more value than basic containment capabilities during their solution evaluation stage. Customized plastic spout caps deliver multiple advantages which enhance user satisfaction while building brand image. The thoughtful design of a cap provides essential benefits which include leak prevention and improved shelf presentation and better dispensing efficiency. A product's competitive market success depends on these combined benefits which unite form and function.

Enhanced Product Functionality and Leak Prevention

Brands choose customized spout caps primarily to achieve leak-proof packaging. The customized cap design matches product containers exactly while providing complete protection through its materials during storage and shipping and product usage. The use of food-grade or chemical-resistant plastics by customized plastic spout caps manufacturers enables compatibility with different product formulations which range from acidic sauces to volatile solvents. The risk of spoilage together with customer complaints decreases while improved shelf life and maintained consumer trust stand as the result.

Better Consumer Convenience and Usability

Modern consumers seek convenience in their purchases so packaging solutions that enhance usability will gain more popularity in the market. Custom spout caps offer various design options including flip-tops and child-safe locks and tamper-evident features and directional nozzles for user-friendly operation. The design of a cleaning product should include a twist-open spout for precise dispensing and baby food pouches should include a wide-mouth cap for effortless feeding. Small product enhancements deliver major effects on customer satisfaction levels as well as brand loyalty magnitude.

Industries that Benefit Most from Custom Plastic Spout Caps

The requirement for specialized packaging solutions extends beyond one specific sector. Various industries now depend on customized plastic spout caps to satisfy changing consumer demands while fulfilling specific product specifications. Businesses from all sectors can enhance product quality and branding through caps which match their product specifications and customer usage patterns.

Food and Beverage Industry Applications

Food manufacturers use spout caps as essential components for precise dispensing of sauces and oils and honey and condiments. Customized caps provide both sanitary usage along with reduced product waste while enhancing the look of the product. Salad dressing bottles with squeezable design and narrow spouts enable users to dispense their contents without creating spills. The manufacturers of customized plastic spout caps select food-safe BPA-free materials that follow regulatory standards while preserving flavor integrity.

Household Cleaning and Chemical Products

Industrial and domestic chemical containers require protective packaging solutions which deliver secure performance. The design of custom spout caps achieves two functions: protecting aggressive formulas from leaking and providing precise flow regulation. Packages of household chemicals typically feature built-in safety features that include locking devices and child-defense mechanisms. The caps used for bleach and floor cleaner products must endure corrosion while maintaining their sealing capabilities. Special use cases can be handled through customized packaging solutions which include spray attachments and dilution caps.

Personal Care and Cosmetic Packaging

Aesthetic appearance combined with easy usage remains essential factors when designing personal care product packages. The packaging of shampoos and body lotions and facial cleansers requires easy-to-open caps which function consistently when used with wet hands. The customized plastic spout caps in this segment receive soft-touch finishes and metallic coloring and ergonomic shapes to match luxurious branding. The spout cap maintains proper product usage while matching the product's visual design.

Baby and Childcare Product Solutions

Infant and child products need to meet both safety requirements and user-friendly standards. The design of custom caps for baby food and formula and lotion includes wide openings and spill-proof valves together with soft squeezable materials. The tamper-evident design approach provides peace of mind to parents regarding product integrity. A well-designed cap enables caregivers to perform daily tasks more easily because they frequently handle their child with one hand.

Automotive and Industrial Lubricants

Packaging requirements for this challenging market demand products that are robust yet exact and protected at all times. The design of custom spout caps targets lubricants and greases and technical fluids by combining chemical resistance with precise application delivery systems. Threaded closures and nozzle tips along with drip-free designs represent popular features in the market. Customization becomes essential because spout caps need to endure both temperature changes and physical abuse that occurs during transportation and workshop activities.

How to Choose the Right Custom Spout Cap Manufacturer

The selection of a proper manufacturer for customized plastic spout caps stands as a vital decision which directly shapes product quality together with lead time and long-term expenses. Apart from standard manufacturing services your ideal partner must understand your industry requirements and provide customizable options while upholding high quality standards throughout the process. A manufacturer who excels in their role will function as an integral part of your product development team to transform concepts into dependable packaging solutions.

Why Choose the Custom Spout Cap Manufacturer Xinda Pelosi?

Xinda Pelosi stands out as a trusted customized plastic spout caps company through its dedication to innovation and production efficiency and quality control systems. China-based Xinda Pelosi delivers complete plastic caps and closures solutions from mold design through bulk manufacturing operations in world. Their product range spans numerous spout caps that serve both food and cosmetics as well as chemical and industrial sectors. The packaging solutions delivered by Xinda Pelosi match perfectly with brands searching for substantial quantities of reliable and customizable packaging.

Common Mistakes to Avoid When Customizing Spout Caps

The process of customizing spout caps extends past design selection since it demands thorough evaluation of technical requirements and user convenience alongside production feasibility. New brands that develop packaging often encounter standard mistakes leading to production delays or performance issues. The avoidance of these errors will lead to an improved process between concept development and commercial launch.

Ignoring Material Compatibility with Product Formulas

Every product formula requires different plastic materials to perform effectively. The combination of harsh oils and aggressive solvents weakens specific plastic materials that eventually results in product leakage and contamination. The selection of materials for your formula needs to match its chemical properties particularly in household chemical and automotive fluid industries. A reliable plastic spout caps manufacturer will help customers select appropriate materials to guarantee both product safety and extended durability.

Overlooking User Experience in Cap Design

Products with attractive caps that users find hard to operate will lead to consumer frustration which damages brand reputation. The ideal time for usability testing appears in early development stages through prototype assessments and real user participation. Assess the usability factors which include how easy it is to hold and the amount of force needed to open it and the ability to control the dispensing mechanism and single-handed operation.

Skipping Functional Testing Before Mass Production

The production of large quantities requires functional tests to check for sealing performance and compatibility and pressure resistance and accurate dispensing. Product recalls or field performance failures will occur when testing is not conducted.

Choosing Style Over Structural Integrity

The visual attractiveness of a product needs to remain in balance with its operational requirements. The delicate nature of a design might fail to endure transportation requirements as well as multiple uses. Performance standards must be met by your custom cap design before you begin to focus on its appearance.

Failing to Align Cap Design with Filling and Sealing Machines

A functional and attractive cap becomes worthless when it cannot integrate with your manufacturing equipment. The design phase should include evaluations of automatic filling and capping machine compatibility to prevent both expensive tool changes and production delays.

Conclusion

Modern packaging now heavily depends on customized plastic spout caps because they enhance both package functionality and brand visibility. Companies seeking packaging excellence should leverage customized plastic spout caps because they fulfill industry needs and consumer preferences while enhancing product features. Businesses can achieve market success through their product lines by integrating customized spout caps provided they understand the benefits and learn to avoid typical implementation challenges.

If you need dependable assistance with packaging innovation then Xinda Pelosi stands ready to serve your needs. Xinda Pelosi provides expertly engineered plastic spout caps to customers through precise operations and fast delivery with flexible capabilities. The company stands as the preferred manufacturer of customized plastic spout caps for businesses which prioritize both quality standards and personalized solutions through their industry expertise and complete service system. Xinda Pelosi offers packaging solutions to enhance your products so contact them now(https://www.xindaplasticcap.com/contact.html) to begin your next project.

6 Applications of Flip Caps in Daily Life: Applications You Never Noticed

Customize Lotion Dispenser Pump Manufacturers in USA

Liquid Pouch vs. Bottles: Which Packaging Saves More Costs?

The Importance of Ergonomic Design in Plastic Trigger Sprayers

Top 10 flip top caps suppliers brands

For Customization

Could you make my own design ?

Yes, it is welcome. Please send us your design document in PDF, CDR, or AI format.

For payment

Payment terms:

If a sample cost, usually we use Western Union and PayPal payments. If the order amount is large, we usually use T/T payment. 50% T/T by deposit, 50% T/T By balance, we also accepted it. Before confirming the order, we would discuss it with each other.

What is your terms of payment?

We accept payment as below:

1. 30% T/T deposit, 70% balance before delivery.

2. 100% T/T in advance for a small payment.

For application

What's the usage for your products?

shampoo, gel, cream lotion, etc.

For after-sales

To whom should we send our complaint about your product or service?

Please kindly write down your complaint with all the details and send it to us.Our Complaint Handling Center will reply to you in 24 hours.

You may also like

We provide a variety of packaging solutions to both small and large businesses and service numerous industries, including beauty and personal care, food and beverage, household and industrial chemicals, and veterinary care.

Get in touch with Xinda pelosi

Have any questions or queries about our products? Please leave us a message here and our team will get back to you promptly.

Your inquiries, ideas, and collaboration opportunities are just a click away. Let's start the conversation.

* Rest assured that your privacy is important to us, and all information provided will be handled with the utmost confidentiality.

Scan QR Code

Scan QR Code

Whatsapp: +8613640286461